Car Impact (comparison: 1930s & today)

The dangers from vehicle impact are;

a) incursion and movement of dangerous objects in its cabin, and;

b) resultant force

The following study does not evaluate the effects of dangerous objects, which are improved by design/removal; it only evaluates the change in impact force for vehicles from the 1930s to today.

Mathematical Principle

A moving object has kinetic energy (½mv²), which is measured in Joules (N.m)

An impacted object absorbs energy by deformation (Fy), which is also measured in Joules (N.m)

The force (F) experienced during an impact is therefore dependent upon the amount of deformation. Too much deformation and the occupants will be crushed, too little and the force will be excessive. Ignoring losses; F = ½mv² ÷ y

The optimum compromise is to allow as much deformation of a car’s body (largest value for ‘y’) without affecting the integrity of the cabin.

Because it is impossible to mathematically generalise vehicle impacts, we have concentrated on the effect of vehicle construction materials, which can be applied meaningfully based upon a representative spring coefficient for the materials involved;

i.e. deformation energy: U = ½ky² where k is the spring coefficient of the impacted materials and is measured in N/m (i.e. in this case, force increases proportionally with deformation)

The elastic modulus of materials (Young’s modulus for steel and flexural modulus for polymers) is measured in N/m² and valid for materials that remain within their elastic stress range. Whilst this is invariably not the case in most impact scenarios, i.e. all materials will deform plastically if the impact is sufficiently intense, the greatest force resisting impact deformation comes from elastic deformation. After plastic deformation has occurred, two things will transpire;

a) as-yet undeformed material will provide greater resistance than that already deformed, and;

b) plastically deformed material that has not split (broken) will relax in its revised shape, work-harden and again deform elastically.

Whilst the theory is not exact, it is entirely representative for the purposes of comparison.

The flexural or Young’s modulus of a material multiplied by its thickness is therefore considered to be a reasonable spring coefficient (k = E.t) for comparative impact scenarios.

Construction Principles

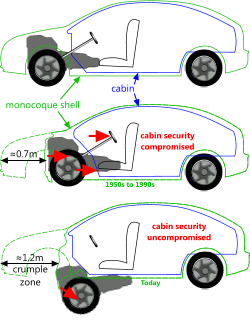

Fig 1. Car Impact Zones

In the 1930s, cars had a steel chassis to which a body was bolted. At that time technology was such that thicker sheet steel was used for its structural members and panels than is considered necessary today.

After the 1950s, cars were manufactured without a chassis. The entire body was a welded/riveted monocoque construction, initially more dangerous for their occupants because cabin deformation was considerably greater than cabins in chassis mounted cars. Early post-1950s cars were also much more prone to the incursion of dangerous objects (steering column, engine, gearbox, etc.) into the cabin.

Today, cars are modular; they’re manufactured in such a way that the cabin remains largely intact in the event of a collision. The front and rear ends provide crumple zones that allow controlled collapse up to, but not including, the cabin. Improved side and head impact protection are the principle reasons as to why modern cars are so much larger than before. The outside surfaces of today’s cars are also more pedestrian-friendly due to the removal of dangerous objects and improvements in materials and shapes (softening).

Most of the potentially dangerous parts that would have caused injury to the occupants in the cabin such as; steering column, suspension system, engine and gearbox, etc. have now been removed completely, designed to collapse or diverted under the cabin in the event of an impact (Fig 1).

Materials

Car chassis in the 1930s were manufactured from heavy gauge⁽³⁾ (≤10g: 3.4mm⁽¹⁾) and difficult to deform longitudinally, therefore, in a high-speed impact, the deformation will be considerably less than in a monocoque or modular constructed car increasing the resultant impact force (F = k ÷ y)

In the 1930s car bumpers were manufactured from 14-gauge carbon steel sheet⁽¹⁾ and the body panels were manufactured from 18-gauge carbon sheet steel.

Monocoque-built cars in the 1950s to 80s were still manufactured from carbon steel, but the bumper thickness was reduced to 18-gauge⁽³⁾ and the body panels were reduced to ≈19-gauge.

Today the external body panels are made from 3mm thick plastics that have a much lower flexural modulus, i.e. they deform more on impact than steel panels, significantly reducing force on impact (F = k ÷ y). Steel structures are now made from aluminium or ≈19-gauge carbon steel or less.

Impact Environments

There are two generally accepted impact environments:

1) Low-Speed Environment (in-town): Car and pedestrian; car and car

2) High-Speed Environment (out-of-town): Car and object (building, tree, another car, etc.)

The pedestrian is considered to be at greatest risk in a car-pedestrian impact, but the risk is considered improvable in a low-speed environment. A high-speed impact with a pedestrian, e.g. on major roads and motorways (i.e. >50mph) would invariably result in serious injury or fatality and would be difficult to avoid by design. It is always preferable to avoid this situation by isolating pedestrians from traffic (see Transport).

A car's occupants are considered to be at greatest risk in the event of a car-object impact, the exposure to injury from which is avoidable even in a high-speed environment (Fig 1).

Formulas

Deformation energy generated by a car deforming under impact and calculated thus: ½k.y²; where k is the spring coefficient for the material

The impact force between any two objects is calculated thus: F = U ÷ y; where U is the deformation energy and y is the deformation

Therefore, F = ½m.v² ÷ y = ½k.y² ÷ y; m.v² ÷ y = k.y; y² = m.v² ÷ k

Spring coefficients for the same component shape or design vary proportionally to the Young’s and flexural moduli of the material from which it has been manufactured (k ≡ E) assuming the same material thickness and shape

Therefore; k = E.T (where: T = material thickness)

and; y² = m.v² ÷ E.T; y = √[m.v² ÷ ET]

Young’s modulus (E) for carbon steel of 2.07E+11 N/m² and flexural modulus (E) for plastics ≈2.5E+09 N/m²⁽²⁾

Low-Speed Environment

The kinetic energy generated by a 1000kg car travelling at 30mph (≈13.5m/s) is;

U = 1000 x 13.5² / 2 = 91125N.m

Car-Pedestrian Impact

For the purposes of comparison (1930s and today):

A car weighing 1000kg with a 14-gauge steel bumper⁽¹⁾;

y = √[m.v² ÷ ET] = √[1000 x 13.5² ÷ 2.07E+11 x 0.002108] = 0.0204m

F = U ÷ y = 91125/0.0204 N = 4459kN

A car weighing 1000kg with a 16-gauge steel bumper;

y = √[m.v² ÷ ET] = √[1000 x 13.5² ÷ 2.07E+11 x 0.001651] = 0.0231m

F = U ÷ y = 91125/0.0231 N = 3946kN

A car weighing 1000kg with an 18-gauge steel bumper;

y = √[m.v² ÷ ET] = √[1000 x 13.5² ÷ 2.07E+11 x 0.001245] = 0.0266m

F = U ÷ y = 91125/0.0266 N = 3426.7kN

A car weighing 1000kg with a 3mm plastic bumper⁽⁴⁾;

y = √[m.v² ÷ ET] = √[1000 x 13.5² ÷ 2.5E+09 x 0.003] = 0.1559m

F = U ÷ y = 91125/0.1559 N = 584.6kN

The above forces take no account of pedestrian deflection in an impact, which would; a) be similar in all of the above cases, and; b) significantly reduce the actual forces.

The force in today's car (3mm plastic bumper) is based upon the assumption that it has 0.156m (6") of collapsible space behind its impacted panel, which is usually the case.

Car-Pedestrian Impact During Braking

Improved stopping distances also affect the impact force and may be calculated as follows (ignoring reaction time {6.75m} which would be similar in all periods):

Speed after 1 second braking from 30mph in the 1950s⁽⁵⁾;

Deceleration: a = (v² – u²) ÷ 2d = (13.5² – 0²) / 2x(34⁽⁵⁾-6.75) = -3.344m/s²

Speed after 1 second: v = u + a.t = 13.5 + -3.344x1 = 10.156m/s (22.7mph)

Speed after 1 second braking from 30mph today;

Deceleration: a = (v² – u²) ÷ 2d = (13.5² – 0²) / 2x(14.9⁽⁵⁾-6.75) = -11.181m/s²

Speed after 1 second: v = u + a.t = 13.5 + -11.181x1 = 2.319m/s (5.2mph)

If you apply the same force calculation to the revised impact velocity (after 1 second braking):

A car weighing 1000kg with a 16-gauge steel bumper;

y = √[m.v² ÷ ET] = √[1000 x 10.156² ÷ 2.07E+11 x 0.001651] = 0.0174m

F = ½m.v² ÷ y = 1000*10.156^2 / 2x0.0174 N = 2968.6kN

A car weighing 1000kg with a 3mm plastic bumper;

y = √[m.v² ÷ ET] = √[1000 x 2.319² ÷ 2.5E+9 x 0.003] = 0.02678m

F = ½m.v² ÷ y = 2688.9/0.02678 N = 100.4kN

Car-Car Impact

Two cars, each weighing 1000kg and 16-gauge steel bumpers;

y = √[m.v² ÷ ET] = √[2000 x 27² ÷ 2.07E+11 x 0.001651] = 0.0653m

F = U ÷ y = 364500/0.0653 N = 5580.6kN

Two cars, each weighing 1000kg and 3mm plastic bumpers and panels;

y = √[m.v² ÷ ET] = √[2000 x 27² ÷ 2.5E+09 x 0.003] = 0.4409m#

F = U ÷ y = 364500/0.4409 N = 826.7kN

A car to car impact would evidently impact the structure# therefore, this calculation should be carried out with 19-gauge steel:

Two cars, each weighing 1000kg and 19-gauge steel structure;

y = √[m.v² ÷ ET] = √[2000 x 27² ÷ 2.07E+11 x 0.001067] = 0.0812m

F = U ÷ y = 364500/0.0812 N = 4486.3kN

The above force is based upon the assumption that today’s cars have 0.441m (17.3") of crumple zone, which is usually the case.

Car-Car Impact During Braking

Improved stopping distances also affect a head-to-head impact force between two cars and may be calculated as follows (ignoring reaction time {6.75m} which would be similar in all periods):

Speed after 1 second braking from 30mph in the 1950s⁽⁵⁾;

Deceleration: a = (v² – u²) ÷ 2d = (13.5² – 0²) / 2x(34⁽⁵⁾-6.75) = -3.344m/s²

Speed after 1 second: V = 2.(u + a.t) = 2x(13.5 + -3.344x1) = 20.312m/s (45.44mph)

Speed after 1 second braking from 30mph today;

Deceleration: a = (v² – u²) ÷ 2d = (13.5² – 0²) / 2x(14.9⁽⁵⁾-6.75) = -11.181m/s²

Speed after 1 second: v = 2.(u + a.t) = 2x(13.5 + -11.181x1) = 4.638m/s (10.375mph)

If you apply the same force calculation to the revised impact velocity (after 1 second braking):

A car weighing 1000kg with a 16-gauge steel bumper;

y = √[m.v² ÷ ET] = √[2000 x (2x20.312)² ÷ 2.07E+11 x 0.001651] = 0.0983m

F = ½m.v² ÷ y = 2000x(2*20.312)² / 0.0983 N = 33585.7kN

A car weighing 1000kg with a 3mm plastic bumper;

y = √[m.v² ÷ ET] = √[2000 x (2x4.638)² ÷ 2.5E+9 x 0.003] = 0.1515m

F = ½m.v² ÷ y = 2000x(2x4.638)² / 0.1515 N = 1136.1kN

High-Speed Environment

The kinetic energy generated by a 1000kg car travelling at 70mph (31.3m/s) is 489845N.m (½m.v²)

Car-Object Impact

A car in a high-speed impact will deform the chassis of a 1930s car and the structural frame of a modern car. For the purposes of this calculation, it will be assumed that a 1950s monocoque frame is manufactured from 16 gauge steel the modern car’s structural frame is made from 19 gauge steel and the greater resistance of pushing the engine through the bulkhead of a 1930s and 1950s car will be ignored (conservative approach):

A 1930s car weighing 1000kg with a 10-gauge steel chassis;

y = √[m.v² ÷ ET] = √[1000 x 31.3² ÷ 2.07E+11 x 0.0034] = 0.0373m

F = U ÷ y = 489845/0.0373 N = 13129kN

A 1950s car weighing 1000kg with a 16-gauge steel chassis;

y = √[m.v² ÷ ET] = √[1000 x 31.3² ÷ 2.07E+11 x 0.001651] = 0.0535m

F = U ÷ y = 489845/0.0535 N = 9149kN

A modern car weighing 1000kg with an 19-gauge steel bumper;

y = √[m.v² ÷ ET] = √[1000 x 31.3² ÷ 2.07E+11 x 0.001067] = 0.0666m

F = U ÷ y = 489845/0.0666 N = 7355kN

... assuming there is 0.666m (26") of crumple zone behind the impacting panels of a modern car, which is usually the case (Fig 1)

Car-Object Impact During Braking

Improved stopping distances⁽⁶⁾ also affect the impact force between a car and a stationary object (wall, tree, etc.) and may be calculated as follows (ignoring reaction time {6.75m} which would be similar in all periods):

1950s car travelling at 70mph will stop in:

d = U ÷ F.μ + ½v = 1000x31.3² / 2x3300x0.3 + 31.3/2 = 510.4m

Speed after 2 seconds braking from 70mph in 1950⁽⁵⁾;

Deceleration: a = (v² – u²) ÷ 2d = (31.3² – 0²) / 2x(510.4 – 31.3/2) = -0.99m/s²

Speed after 2 seconds: v = u + a.t = 31.3 + -0.99x2 = 29.32m/s (65.6mph)

Speed after 2 seconds braking from 70mph today;

Deceleration: a = (v² – u²) ÷ 2d = (31.3² – 0²) / 2x(60.2 – 31.3/2) = -11m/s²

Speed after 2 seconds: v = u + a.t = 31.3 + -11x2 = 9.31m/s (20.8mph)

If you apply the same force calculation to the revised impact velocity (after 2 seconds braking):

A car weighing 1000kg with a 16-gauge steel structure;

y = √[m.v² ÷ ET] = √[1000 x 29.32² ÷ 2.07E+11 x 0.001651] = 0.0502m

F = ½m.v² ÷ y = 1000x29.32² / 2x0.0502 N = 8570.2kN

A car weighing 1000kg with 19-gauge structural steel;

y = √[m.v² ÷ ET] = √[1000 x 9.3² ÷ 2.07E+11 x 0.001067] = 0.0198m

F = ½m.v² ÷ y = 1000x9.31² / 2x0.0198 N = 2187.5kN

Conclusions

The following table summarises the improvements (reduction) in impact force during a collision between a car and other objects since the 1950s

| Environment | Impact Force (kN) | ||

|---|---|---|---|

| Low-Speed | 1950s | Today | Improvement |

| Car & Pedestrian @ 30mph | 3946.0 | 584.6 | 85.2% |

| Car & Pedestrian 1s after braking | 2968.6 | 100.4 | 96.6% |

| Car & Car @ 30mph | 5580.6 | 4486.3 | 19.6%# |

| Car & Car @ 30mph 1s after braking | 8396.4 | 284.0 | 96.6% |

| High-Speed | |||

| Car & stationary object @ 70mph | 9149.0 | 7355.0 | 19.6%# |

| Car & stationary object @ 70mph 2s after braking | 8570.2 | 2187.5 | 74.5% |

# This figure is substantially greater in reality for most cars today as in-cabin safety improvements have not been included in the above calculations: e.g. modular construction, impact-protection members, airbags, seatbelts, collapsible or non-existent steering column, stronger seats, etc.

The above calculations are not intended as a detailed and/or specific analysis of vehicle impacts over the periods concerned, that would be an impossible task given that every impact is different, e.g.; the car (construction), the road conditions, impact configuration, driver and pedestrian behaviour, etc.

These calculations are a representative comparison of the consequences of car construction improvements on vehicle impact over the last 80 years.

Notes

- Typical structural steel thickness for a 1930s’ car

- Typical flexural modulus for plastics used in the manufacture of car panels (N/mm²) : PA: 3100, PC: 2300, PEI: 2400, PEEL: 750, PPE: 3800, PP: 1400, PUR: 3000, TPO: 1800

- Gauge thickness converter (http://www.mesteel.com/cgi-bin/w3-msql/goto.htm?url=/info/carbon/thickness.htm)

- Physically measured by a CalQlata member on the body panel of a 2013 car

- Comparison between the stopping distances of cars of the 1930’s and those of today would be almost meaningless as the difference is so substantial (96.6m & 14.9m; see stopping distances)

- In the 1950s, brakes were less efficient at stopping a vehicle that tyres (see Tyres & Brakes Together)