Machining Tolerances Calculator (limits and fits)

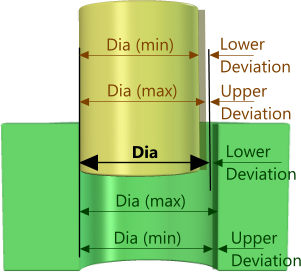

Fig 1. Machining Tolerances

In order to ensure that any machined shaft and mating hole fit exactly as required, irrespective of where and how they were made, it is necessary to apply suitable tolerances to internationally recognised standards. The two best known standards for this process are ISO 286-1:2010 and ANSI B4.1 & 2

Some of the benefits of this standardisation are:

1) Optimum design life

2) Ease of assembly

3) Correct assembly condition

4) Correctly fitting replacement parts

5) Multiple suppliers

6) No more trial and error machining

Some standard fits are listed below:

ISO:

| Fit | Hole# | Shaft# | Description |

|---|---|---|---|

| Loose Running | H11/c11 | C11/h11 | Wide commercial tolerances or allowances on external members |

| Free Running | H9/d9 | D9/h9 | Not for use where accuracy is essential but good for large temperature variations, high running speeds or heavy journal pressures |

| Close Running | H8/f7 | F8/h7 | Running on accurate machines and for accurate location at moderate running speeds or journal pressures |

| Sliding | H7/g6 | G7/h6 | Not intended to run freely but to move and turn freely and locate accurately |

| Locational Clearance | H7/h6 | H7/h6 | Snug fit for locating stationary parts but can be freely assembled and disassembled |

| Locational Transition | H7/k6 | K7/h6 | Accurate location with a compromise between clearance and interference |

| Locational Transition (tight) | H7/n6 | N7/h6 | More accurate location where greater interference is permissible |

| Locational Interference | H7/p6 | P7/h6 | Parts requiring rigidity and alignment with prime accuracy of location but without special bore pressure requirements (can be separated) |

| Medium Drive | H7s6 | S7/h6 | Ordinary steel parts or shrink fit on light sections. Tightest fit useable with cast iron |

| Force | H7/u6 | U7/h6 | Suitable for parts that can be highly stressed or for shrink fits where heavy pressing forces are impractical |

Hole#: hole governs fit/sizing

Shaft#: shaft governs fit/sizing

ANSI:

| Fit | Hole | Description |

|---|---|---|

| RC1 | H5/g4 | Close sliding fit for accurate location and no noticeable play |

| RC2 | H6/g5 | Parts made to fit, move and turn easily but not intended to run freely |

| RC3 | H7/f6 | Closest free-running fit (low-speed & ht pressures), but will seize under small temperature variations |

| RC4 | H8/f7 | Close running fit for accurate machinery under moderate speeds and bearing pressures (accurate location and minimum play) |

| RC5 | H8/e7 | Running fit for medium speeds and bearing pressures and exposure to small temperature variations |

| RC6 | H9/e8 | Free running fit for medium speeds and bearing pressures and exposure to moderate temperature variations |

| RC7 | H9/d8 | Free running fit for high speeds and bearing pressures where accuracy is not important and exposure to large temperature variations |

| RC8 | H10/c9 | Loose running for wide commercial tolerances |

| RC9 | H11/c0 | Loose running for wide commercial tolerances (maximum play) |

| LC1 | H6/h5 | Most accurate location where running and sliding is not required and ease of assembly is not important (least play) |

| LC2 | H7/h6 | Location clearance fit |

| LC3 | H8/h7 | Location clearance fit |

| LC4 | H10/h9 | Location clearance fit |

| LC5 | H7/g6 | Location clearance fit |

| LC6 | H9/f8 | Location clearance fit |

| LC7 | H10/e9 | Location clearance fit |

| LC8 | H10/d9 | Location clearance fit |

| LC9 | H11/c10 | Location clearance fit |

| LC10 | H12/c0 | Location clearance fit |

| LC11 | H13/c0 | Least accurate location where running and sliding is not required but easy assembly is essential (most play) |

| LT1 | H7/js6 | Location transition fit (lowest possible interference) |

| LT2 | H8/js7 | Location transition fit |

| LT3 | H7/k6 | Location transition fit |

| LT4 | H8/k7 | Location transition fit |

| LT5 | H7/n6 | Location transition fit |

| LT6 | H7/n7 | Location transition fit (highest possible interference) |

| LN1 | H6/n5 | Location interference fit (least interference) |

| LN2 | H7/p6 | Location interference fit |

| LN3 | H7/r6 | Location interference fit (most interference) |

| FN1 | H6/c0 | Light drive fit for low assemby pressures (thin sections or long fits) |

| FN2 | H7/s6 | Medium drive fit for ordinary steel parts or shrink fits on light sections (tightest fit for high-grade cast iron) |

| FN3 | H7/t6 | Heavy drive fit for heavy sections or shrink fit for medium sections |

| FN4 | H7/u6 | Force fit for parts that can be highly stressed or shrink fit where heavy pressing forces are impractical |

| FN5 | H8/x7 | Highest force fit for parts that can be highly stressed or shrink fit where heavy pressing forces are impractical |

Holes govern sizing

RC = rolling clearance

LC = location clearance

LN = location interference

LT = location transition

FN = force interference

Machining Tolerances Calculator - Technical Help

You enter a basic diameter (Fig 1; Dia) and select your desired fit from the calQlation options and Limits and Fits will automatically calculate the machining tolerances (maximum and minimum diameters) for both the Hole and the Shaft.

When entering your diameter, you must ensure that you have selected the correct input units (millimetres or inches).

Click your mouse button on the blue text 'Diameter: mm' to change the units to Imperial ins

or

Click your mouse button on the blue text 'Diameter: ins' to change the units to metric mm

You can also create your own 'non-standard' fit by simply selecting the hole/shaft grades you require and the machining tolerances will be calculated for you.

Further Reading

You will find further reading on this subject in reference publications(2)